◆Introduction to processing principle

For the waste slurry produced in the process of crystal cutting, the system recovers its effective substances (silicon carbide and polyethylene glycol) and removes impurities (silicon powder, etc.), so as to ensure the relevant indicators and cutting capacity of slurry recovery and reuse again.

◆Introduction to equipment principle

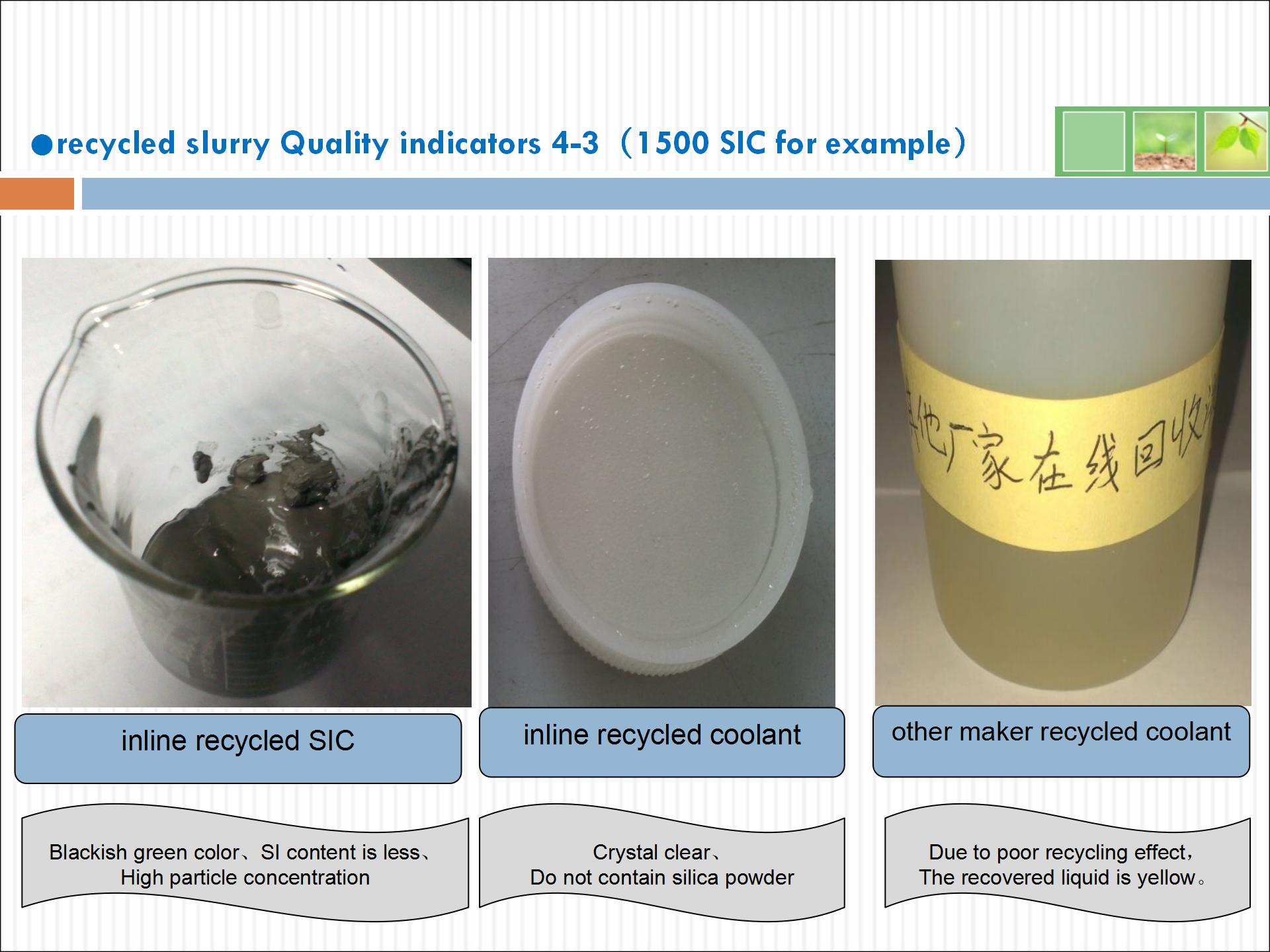

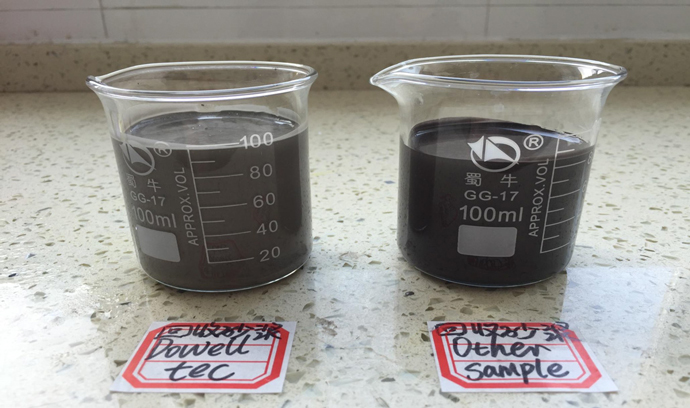

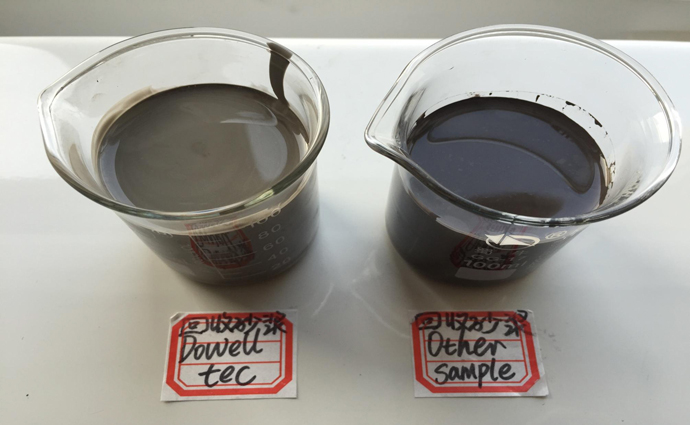

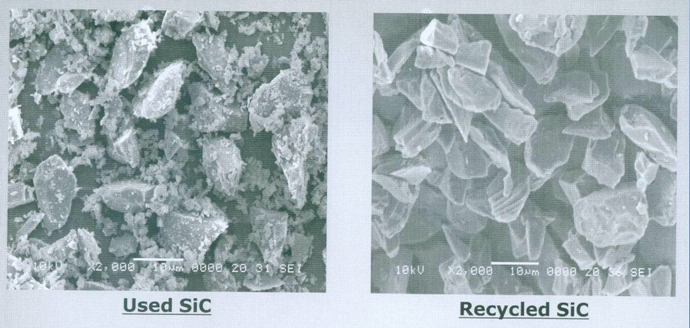

The equipment separates the effective and ineffective components in the slurry through the low-speed separater and matches the special process to make the recovered silicon carbide have the characteristics of centralized particle size distribution, appropriate D50 value and overall average roundness value meeting the production needs. In addition, the liquid separation equipment can completely restore the purity of the recovered liquid and ensure that the small particles in the recovered liquid are removed. The user can choose the cutting liquid evaporation system according to the situation.

◆Green environmental protection

The equipment adopts advanced treatment process, does not add any chemical agent in the recycling process, and has a small amount of waste (no waste water). It not only achieves economic benefits, but also meets the requirements of environmental protection.

Schematic diagram of recycling process

cutting used sic & 对比图

Results image

Jiangyin Dowell Reuse Technology Co., Ltd.

Address: Floor 10, Baiqiao Biological Park, No. 85, Shashan Road, high tech Zone, Jiangyin City, Jiangsu Province

contacts: Linghai

Telephone: (0510) 8699-5065

Su ICP Bei No. 18067166